Description

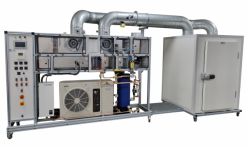

The educational air handling unit (AHU) incorporates the following elements:

- An insulated box to simulate an atmosphere for air handling units;

- A system of hot and cold batteries and a humidification system to achieve a given set point in the room box (heating and humidification regulation);

- Possibility of recirculating treated air (20-100%) with manual damper or automatic regulation ;

- Ability to control each AHU component (register, cold coil, hot coil and humidifier) in manual or automatic mode

- Instrumentation for humidity and temperature measurements, as well as for electrical power measurements;

- Measurements can be taken directly on the bench or recorded in a spreadsheet file via data acquisition software that also allows real-time visualization.

The CRA535 bench allows the study of a double flow air handling unit (two fans). It consists of the classic elements of a treatment network, namely: filters, a cold coil, a chiller, a humidifier, a hot coil, a supply fan, a return fan and mixing dampers. A box is connected to the supply and return ducts to simulate a part to be regulated. The box is based on an insulated cold room to reduce heat loss

Students will first have to identify the components of the plant and the directions of air circulation.

They will then have to put the system into operation according to the conditions set by the teacher, air conditioning mode or heating mode and manual mode or automatic mode (regulation).

Once the operating regime is established, they will have to measure the operating parameters (temperature, humidity, air flow, etc.) with the fixed instrumentation.

The next task is to exploit the measurements by plotting the air cycle on a psychrometric diagram and calculating the powers of the exchangers.

Students will be able to vary the conditions and see the influence on the yields and efficiency of the system.

The rugged design of this equipment makes it perfectly suited for use in a school setting.

Its anodized aluminum structure on wheels gives it great robustness as well as great flexibility of integration into your premises.

The manufacture of this equipment complies with the European Machinery Directive